Chemicals, oils, burrs, and other kinds of residue from the fabrication process must be removed from the surface of parts before they can undergo surface finishing. Coatings such as electroplating and zinc cannot be effectively applied over dirt or grease. Read More…

Niagara Systems LLC has offered turnkey custom parts washing systems for over 80 years. With our customization capabilities, our parts washing systems stand out from the competition.

Great Lakes Finishing Equipment, Inc. specializes in supplying parts washers for even the most demanding cleaning jobs. Equipment includes table washers, drum washers, aqueous rotary baskets, aqueous belt washing systems, & more. Let our parts washing specialists assist you with your specific washing applications. Contact us today for all of your parts washer needs.

Need help with a parts washer to clean your dirty parts? Contact StingRay to get a quote for an engineered parts washer. StingRay Parts Washer offers a complete solution to your cleaning needs which includes fixturing of your parts, industry approved detergent, engineered parts washer, and the most complete customer service in the industry.

More Parts Cleaner Manufacturers

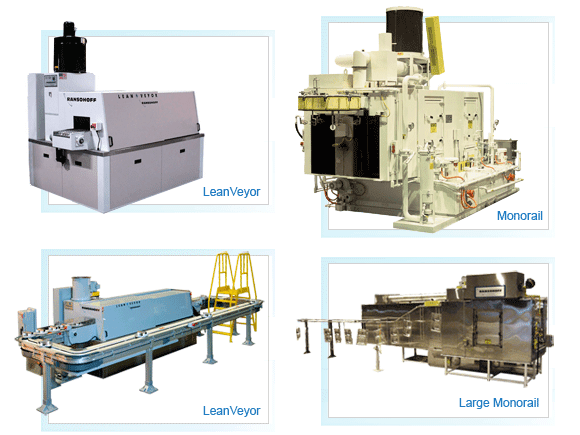

Industrial washers, an example of a parts cleaner, may be designed as multi-stage processes, deburring, cleaning, drying, surface treating, and even coating all in one application. Other parts washing machinery may be as simple as a single-stage immersion aqueous parts washing tub.

Parts cleaners use water, aqueous chemical solutions, ultrasonic blasts, and agitation to clean part surfaces; sometimes non-aqueous methods such as acoustic cleaning, vapor cleaning, vibration cleaning, and laser ablation are used. Many parts cleaners use aqueous parts washing to remove surface oils, although non-aqueous methods are sometimes used when aqueous cleaning is impossible.

The two main methods aqueous parts cleaners use are spray washing and immersion washing. Immersion washing, which is also known as agitation, immerses parts in a hot organic or water-based chemical solvent in a mesh basket that turns, rotates, and shakes dirt off of the parts. Immersion washers can be as simple as a tub in which parts are placed or removed, or they can be a series of tubs with different washing solvents and automated arms. Spray washers, on the other hand, utilize a series of spray nozzles to project a pressurized organic or water-based solution onto the parts being cleaned.

Until very recently, most aqueous parts washing solvents have been chemical-based, but the recent emergence of environmental and worker safety concerns and regulations have made the use of organic solvents more common.

Ultrasonic cleaning is an innovative precision cleaning method that requires much smaller solvent concentrations than traditional washing; this cuts down on harmful and expensive waste. Tiny air blasts burst against parts' surfaces, cleaning in crevices that other washing techniques can't reach. Automotive parts washers often use ultrasonic cleaning to reduce the risk of malfunction due to part contamination. Surgical, dental and electronics parts washing often involve ultrasonic cleaning as well.

In industries that depend on exactness and precision, contamination by oil, grease, or dirt can mean the difference between smoothly operating machinery and loss of thousands of dollars or even lives. Parts cleaners are invaluable in industrial manufacturing, not only because they provide thorough cleaning solutions, but because they also reduce labor costs.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services